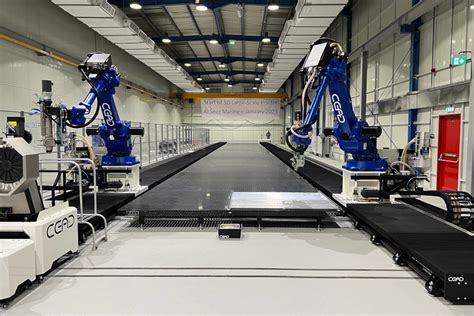

The marine industry has long been at the forefront of innovation, with advancements in technology transforming the way ships are designed, built, and operated. One area that has seen significant growth in recent years is the use of 3D printing, also known as additive manufacturing. Tech Marine STL is a company that has been at the forefront of this trend, utilizing 3D printing to create innovative solutions for marine applications.

The use of 3D printing in the marine industry offers a number of benefits, including increased efficiency, reduced costs, and improved performance. By creating complex shapes and structures layer by layer, 3D printing allows for the creation of components that would be impossible to produce using traditional manufacturing methods. This has opened up new possibilities for the design and development of marine vessels, from propellers and thrusters to engine components and even entire hulls.

Benefits of 3D Printing in Marine Applications

One of the primary benefits of 3D printing in marine applications is the ability to create complex geometries that cannot be produced using traditional manufacturing methods. This allows for the creation of components with improved performance, reduced weight, and increased efficiency. For example, 3D printed propellers can be designed with complex shapes that improve their efficiency and reduce drag, resulting in increased fuel efficiency and reduced emissions.

Another benefit of 3D printing in marine applications is the reduced lead time and increased flexibility. Traditional manufacturing methods can take weeks or even months to produce complex components, whereas 3D printing can produce them in a matter of days or even hours. This allows for rapid prototyping and testing, reducing the time and cost associated with traditional manufacturing methods.

Applications of 3D Printing in Marine Industry

The applications of 3D printing in the marine industry are vast and varied. Some of the most promising areas of research and development include:

- Propellers and thrusters: 3D printed propellers and thrusters can be designed with complex shapes that improve their efficiency and reduce drag.

- Engine components: 3D printed engine components can be designed with complex geometries that improve their performance and reduce weight.

- Hulls and superstructures: 3D printed hulls and superstructures can be designed with complex shapes that improve their strength and reduce weight.

Challenges and Limitations of 3D Printing in Marine Applications

While 3D printing offers a number of benefits for marine applications, there are also several challenges and limitations that must be addressed. One of the primary challenges is the limited availability of materials that are suitable for marine applications. The marine environment is harsh and corrosive, and materials must be able to withstand the stresses and strains of the sea.

Another challenge is the lack of standardization and regulation in the 3D printing industry. There is currently a lack of standards and regulations governing the use of 3D printing in marine applications, which can make it difficult to ensure the quality and safety of 3D printed components.

Future of 3D Printing in Marine Industry

Despite the challenges and limitations, the future of 3D printing in the marine industry looks bright. As the technology continues to evolve and improve, we can expect to see increased adoption and application of 3D printing in a wide range of marine applications.

One area that is likely to see significant growth is the use of 3D printing for maintenance and repair. By creating spare parts and components on demand, 3D printing can reduce the time and cost associated with traditional manufacturing methods, improving the efficiency and effectiveness of maintenance and repair operations.

Conclusion and Recommendations

In conclusion, 3D printing is a rapidly evolving technology that has the potential to transform the marine industry. From propellers and thrusters to engine components and even entire hulls, 3D printing offers a number of benefits, including increased efficiency, reduced costs, and improved performance.

However, there are also several challenges and limitations that must be addressed, including the limited availability of materials and the lack of standardization and regulation.

To realize the full potential of 3D printing in marine applications, we recommend the following:

- Increased investment in research and development to improve the availability and performance of materials suitable for marine applications.

- Development of standards and regulations governing the use of 3D printing in marine applications.

- Increased adoption and application of 3D printing in a wide range of marine applications, including maintenance and repair.

By addressing these challenges and limitations, we can unlock the full potential of 3D printing in the marine industry, improving efficiency, reducing costs, and enhancing performance.

What is 3D printing in marine applications?

+3D printing in marine applications refers to the use of additive manufacturing technology to create complex components and structures for marine vessels.

What are the benefits of 3D printing in marine applications?

+The benefits of 3D printing in marine applications include increased efficiency, reduced costs, and improved performance.

What are the challenges and limitations of 3D printing in marine applications?

+The challenges and limitations of 3D printing in marine applications include the limited availability of materials, lack of standardization and regulation, and high costs.