Effective machinery maintenance is crucial for industries that rely heavily on equipment to ensure smooth operations, prevent breakdowns, and reduce costs. A well-planned maintenance schedule can help organizations achieve these goals by identifying potential issues before they occur. In this article, we will explore the importance of machinery maintenance, its benefits, and how to create a maintenance schedule using an Excel template.

Importance of Machinery Maintenance

Machinery maintenance is essential for any industry that uses equipment to produce goods or provide services. Regular maintenance can help prevent unexpected breakdowns, reduce downtime, and increase overall efficiency. By performing routine maintenance tasks, organizations can identify potential issues before they become major problems, reducing the risk of accidents and injuries.

Benefits of Machinery Maintenance

Regular machinery maintenance offers numerous benefits, including:

- Reduced downtime: By performing routine maintenance tasks, organizations can reduce the risk of unexpected breakdowns, minimizing downtime and increasing productivity.

- Increased efficiency: Well-maintained equipment operates more efficiently, reducing energy consumption and increasing overall productivity.

- Improved safety: Regular maintenance can help identify potential safety hazards, reducing the risk of accidents and injuries.

- Extended equipment lifespan: Proper maintenance can extend the lifespan of equipment, reducing the need for costly repairs and replacements.

Creating a Machinery Maintenance Schedule

Creating a machinery maintenance schedule can help organizations ensure that equipment is properly maintained and reduce the risk of breakdowns. Here are the steps to create a maintenance schedule:

- Identify equipment: Make a list of all equipment that requires maintenance, including machinery, tools, and vehicles.

- Determine maintenance tasks: Identify the maintenance tasks required for each piece of equipment, including routine checks, cleaning, and repairs.

- Schedule maintenance: Create a schedule that outlines the maintenance tasks and frequencies for each piece of equipment.

- Assign responsibilities: Assign maintenance tasks to specific personnel or teams, ensuring that each task is completed on time.

- Monitor and review: Regularly monitor and review the maintenance schedule to ensure that tasks are being completed and equipment is properly maintained.

Machinery Maintenance Schedule Template Excel

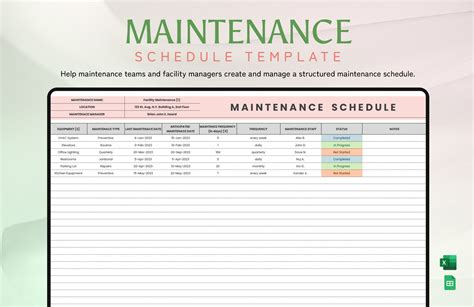

Using an Excel template can help organizations create a comprehensive maintenance schedule. Here are the key components of a machinery maintenance schedule template Excel:

- Equipment list: A list of all equipment that requires maintenance, including machinery, tools, and vehicles.

- Maintenance tasks: A list of maintenance tasks required for each piece of equipment, including routine checks, cleaning, and repairs.

- Frequency: The frequency of each maintenance task, including daily, weekly, monthly, and quarterly tasks.

- Responsible personnel: The personnel or teams responsible for completing each maintenance task.

- Completion status: A column to track the completion status of each maintenance task.

Free Machinery Maintenance Schedule Template Excel Download

To help organizations create a comprehensive maintenance schedule, we are offering a free machinery maintenance schedule template Excel download. This template includes the key components outlined above and can be customized to meet the specific needs of your organization.

To download the template, click on the link below:

[Insert link to download template]

Customizing the Template

To customize the template, follow these steps:

- Open the template in Excel and save a copy to your computer.

- Review the equipment list and add or remove equipment as necessary.

- Review the maintenance tasks and add or remove tasks as necessary.

- Update the frequency and responsible personnel columns as necessary.

- Use the completion status column to track the completion of each maintenance task.

By following these steps, organizations can create a comprehensive maintenance schedule that helps reduce downtime, increase efficiency, and improve safety.

Conclusion

Effective machinery maintenance is crucial for industries that rely heavily on equipment. By creating a comprehensive maintenance schedule, organizations can reduce downtime, increase efficiency, and improve safety. Using a machinery maintenance schedule template Excel can help organizations create a schedule that meets their specific needs. Download our free template today and start improving your maintenance operations.

Gallery of Machinery Maintenance Schedule Template Excel

What is the importance of machinery maintenance?

+Machinery maintenance is crucial for industries that rely heavily on equipment to ensure smooth operations, prevent breakdowns, and reduce costs.

What are the benefits of machinery maintenance?

+Regular machinery maintenance offers numerous benefits, including reduced downtime, increased efficiency, improved safety, and extended equipment lifespan.

How do I create a machinery maintenance schedule?

+To create a machinery maintenance schedule, identify equipment, determine maintenance tasks, schedule maintenance, assign responsibilities, and monitor and review the schedule.