The importance of proper wiring in fuel systems cannot be overstated. A well-designed and installed wiring system ensures the safe and efficient operation of fuel tech systems, while a poorly designed or installed system can lead to decreased performance, increased emissions, and even safety risks. In this article, we will explore five essential fuel tech wiring diagram tips to help you create a reliable and efficient fuel system.

Fuel tech wiring diagrams are crucial for the installation, troubleshooting, and maintenance of fuel systems. A wiring diagram provides a visual representation of the electrical connections between components, allowing technicians to identify and resolve issues quickly. By following these five essential tips, you can create accurate and informative wiring diagrams that simplify the installation and troubleshooting process.

Tip 1: Use Clear and Consistent Labeling

Clear and consistent labeling is essential for creating a wiring diagram that is easy to understand. Use a standardized labeling system to identify components, wires, and connections. This will help technicians quickly identify the components and connections in the system, reducing the risk of errors and misconnections.

When labeling components, use a clear and concise format that includes the component name, type, and any relevant specifications. For example, "Fuel Pump (FP-123)" or "Fuel Injector (FI-456)". Use a consistent color-coding system to differentiate between different types of wires and connections.

Tip 2: Use Logical and Organized Layout

A logical and organized layout is crucial for creating a wiring diagram that is easy to follow. Use a hierarchical structure to organize the components and connections, with the most critical components and connections prominently displayed.

Use a grid system to align components and connections, and use clear and concise labels to identify each component and connection. Avoid cluttering the diagram with unnecessary information, and use visual aids such as arrows and lines to illustrate the flow of electrical signals.

Tip 3: Include Detailed Component Information

Including detailed component information is essential for creating a wiring diagram that is accurate and informative. Provide detailed specifications for each component, including type, model number, and any relevant specifications.

For example, include the part number, voltage, and current rating for each component, as well as any relevant installation or maintenance instructions. This information will help technicians quickly identify and replace components, reducing downtime and increasing efficiency.

Tip 4: Use Visual Aids to Illustrate Complex Connections

Visual aids such as arrows, lines, and symbols can be used to illustrate complex connections and simplify the wiring diagram. Use these visual aids to show the flow of electrical signals between components, and to identify potential trouble spots.

For example, use arrows to indicate the direction of electrical flow, and use lines to connect components and illustrate the wiring harness. Use symbols to identify different types of connections, such as grounds, power sources, and signal inputs.

Tip 5: Review and Update the Wiring Diagram Regularly

Finally, it is essential to review and update the wiring diagram regularly to ensure accuracy and relevance. As components and connections are added or modified, the wiring diagram should be updated to reflect these changes.

Regularly review the wiring diagram to ensure that it is accurate and up-to-date, and make any necessary changes or updates. This will help ensure that the fuel system operates safely and efficiently, and that technicians can quickly identify and resolve any issues that may arise.

By following these five essential fuel tech wiring diagram tips, you can create accurate and informative wiring diagrams that simplify the installation and troubleshooting process. Remember to use clear and consistent labeling, a logical and organized layout, detailed component information, visual aids to illustrate complex connections, and review and update the wiring diagram regularly.

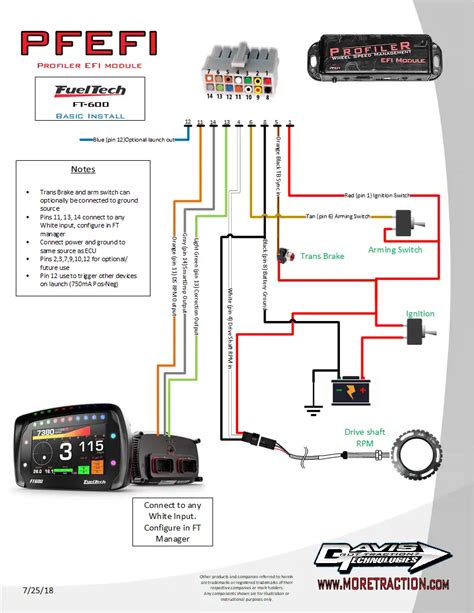

Gallery of Fuel Tech Wiring Diagrams

We hope you found this article helpful in understanding the importance of fuel tech wiring diagrams. If you have any questions or need further assistance, please don't hesitate to ask.