The automobile industry has witnessed significant advancements in recent years, with technological innovations transforming the way cars are designed, manufactured, and repaired. One area that has seen substantial improvements is transmission repair, thanks to the emergence of Nu Tech Transmission. In this article, we will explore five ways Nu Tech Transmission is revolutionizing car repair and why it's becoming a game-changer in the industry.

What is Nu Tech Transmission?

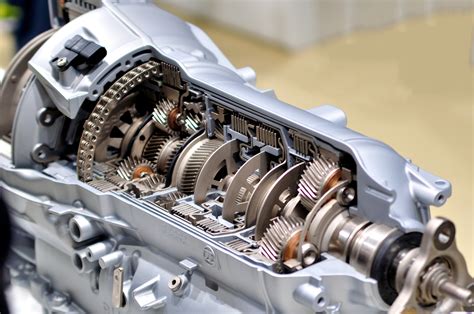

Before we dive into the ways Nu Tech Transmission is transforming car repair, let's briefly understand what it is. Nu Tech Transmission is a cutting-edge technology that utilizes advanced computer-aided design (CAD) software, 3D printing, and robotic manufacturing to produce high-quality transmission components. This innovative approach enables the creation of custom-made transmission parts that are tailored to specific vehicle models, making repairs faster, more efficient, and cost-effective.

1. Faster Repair Times

Traditional transmission repair methods often involve lengthy processes, including manual disassembly, inspection, and reassembly. Nu Tech Transmission's advanced technology streamlines this process by enabling the rapid production of custom-made transmission components. This significantly reduces repair times, getting your car back on the road faster.

How Does it Work?

Nu Tech Transmission's software uses advanced algorithms to analyze the vehicle's transmission data, identifying the specific components required for repair. The system then generates a 3D model of the needed parts, which are subsequently produced using 3D printing technology. This process eliminates the need for manual disassembly and reduces the risk of human error, resulting in faster repair times.

2. Improved Accuracy

Nu Tech Transmission's computer-aided design software ensures that transmission components are manufactured with precise accuracy. This eliminates the risk of human error, which can lead to costly rework or even complete failure of the transmission.

Reducing the Risk of Human Error

Traditional transmission repair methods rely heavily on manual labor, which can lead to mistakes during the disassembly and reassembly process. Nu Tech Transmission's technology minimizes this risk by automating the production of transmission components, ensuring that every part is manufactured to exact specifications.

3. Cost Savings

Nu Tech Transmission's innovative approach to transmission repair can result in significant cost savings for car owners. By producing custom-made transmission components, the technology eliminates the need for expensive replacement parts or manual labor.

Reducing Costs without Compromising Quality

Traditional transmission repair methods often involve purchasing expensive replacement parts or investing in manual labor. Nu Tech Transmission's technology reduces these costs by producing high-quality transmission components at a lower price point. This enables car owners to save money without compromising on the quality of the repair.

4. Increased Efficiency

Nu Tech Transmission's advanced technology enables the rapid production of transmission components, increasing the efficiency of the repair process. This streamlined approach reduces the time spent on manual labor, allowing technicians to focus on more complex repairs.

Streamlining the Repair Process

Traditional transmission repair methods often involve time-consuming manual labor, including disassembly, inspection, and reassembly. Nu Tech Transmission's technology automates the production of transmission components, freeing up technicians to focus on more complex repairs and increasing overall efficiency.

5. Environmental Benefits

Nu Tech Transmission's technology also offers environmental benefits by reducing waste and minimizing the carbon footprint of the repair process. The production of custom-made transmission components eliminates the need for unnecessary replacement parts, reducing waste and the environmental impact of the repair process.

Reducing Waste and Minimizing Carbon Footprint

Traditional transmission repair methods often involve purchasing replacement parts, which can result in unnecessary waste. Nu Tech Transmission's technology reduces waste by producing custom-made transmission components, minimizing the carbon footprint of the repair process.

Gallery of Nu Tech Transmission

Frequently Asked Questions

What is Nu Tech Transmission?

+Nu Tech Transmission is a cutting-edge technology that utilizes advanced computer-aided design (CAD) software, 3D printing, and robotic manufacturing to produce high-quality transmission components.

How does Nu Tech Transmission reduce repair times?

+Nu Tech Transmission's software analyzes the vehicle's transmission data, identifying the specific components required for repair. The system then generates a 3D model of the needed parts, which are subsequently produced using 3D printing technology.

What are the environmental benefits of Nu Tech Transmission?

+Nu Tech Transmission's technology reduces waste and minimizes the carbon footprint of the repair process by producing custom-made transmission components, eliminating the need for unnecessary replacement parts.

Nu Tech Transmission is revolutionizing the car repair industry with its cutting-edge technology, offering faster repair times, improved accuracy, cost savings, increased efficiency, and environmental benefits. As the demand for innovative solutions continues to grow, Nu Tech Transmission is poised to become a leader in the transmission repair market.