In today's competitive business landscape, organizations are constantly seeking ways to improve efficiency, reduce waste, and enhance customer satisfaction. One powerful tool that has gained popularity in recent years is Value Stream Mapping (VSM). By visualizing and analyzing the flow of materials and information, VSM helps teams identify areas of improvement and implement lean principles to achieve success. In this article, we will explore the benefits of VSM, provide a free downloadable template, and offer guidance on how to apply this tool to drive lean success.

What is Value Stream Mapping?

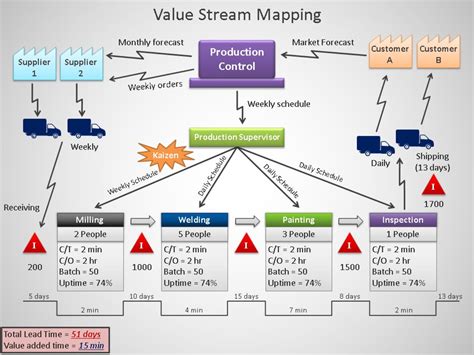

Value Stream Mapping is a visual representation of the flow of materials and information across a process or system. It is a powerful tool used to identify waste, optimize workflows, and improve efficiency. VSM is an essential component of lean methodology, which aims to minimize waste and maximize value for customers.

Benefits of Value Stream Mapping

The benefits of VSM are numerous and can have a significant impact on an organization's bottom line. Some of the most significant advantages of VSM include:

- Improved efficiency: By identifying and eliminating waste, organizations can streamline processes and reduce lead times.

- Increased productivity: VSM helps teams focus on high-value activities, leading to increased productivity and better resource allocation.

- Enhanced customer satisfaction: By understanding customer needs and expectations, organizations can design processes that meet those needs, leading to higher customer satisfaction.

- Reduced costs: By minimizing waste and optimizing workflows, organizations can reduce costs and improve profitability.

How to Create a Value Stream Map

Creating a Value Stream Map is a straightforward process that involves several steps:

- Define the scope: Identify the process or system to be mapped and define the boundaries.

- Gather data: Collect data on the current state of the process, including lead times, cycle times, and waste.

- Map the current state: Use the data to create a visual representation of the current state, including all steps, processes, and material flows.

- Identify waste: Analyze the map to identify areas of waste, including transportation, inventory, motion, waiting, overproduction, overprocessing, and defects.

- Design the future state: Use the insights gained from the current state map to design a future state that eliminates waste and optimizes workflows.

Value Stream Mapping Template

To help you get started with VSM, we are offering a free downloadable template. This template includes all the necessary elements to create a comprehensive Value Stream Map, including:

- Process boxes: Used to represent each step in the process.

- Material flow arrows: Used to represent the flow of materials between steps.

- Information flow arrows: Used to represent the flow of information between steps.

- Waste symbols: Used to identify areas of waste.

Download the Value Stream Mapping Template here: [Insert link]

Best Practices for Value Stream Mapping

To ensure success with VSM, follow these best practices:

- Involve stakeholders: Engage with stakeholders across the organization to ensure that the map accurately represents the current state.

- Use data: Use data to inform the mapping process and identify areas of waste.

- Focus on the customer: Keep the customer in mind when designing the future state.

- Keep it simple: Avoid complexity and focus on simplicity and clarity.

Common Mistakes to Avoid

When implementing VSM, avoid these common mistakes:

- Insufficient data: Failing to gather sufficient data can lead to inaccurate maps and ineffective improvements.

- Lack of stakeholder engagement: Failing to engage with stakeholders can lead to resistance to change and ineffective implementation.

- Overemphasis on technology: Focusing too much on technology can lead to neglect of other important factors, such as process and people.

Conclusion

Value Stream Mapping is a powerful tool for achieving lean success. By visualizing and analyzing the flow of materials and information, organizations can identify areas of improvement and implement lean principles to drive efficiency, productivity, and customer satisfaction. By following the best practices outlined in this article and avoiding common mistakes, organizations can unlock the full potential of VSM and achieve sustainable success.

Gallery of Value Stream Mapping

FAQ Section

What is Value Stream Mapping?

+Value Stream Mapping is a visual representation of the flow of materials and information across a process or system.

What are the benefits of Value Stream Mapping?

+The benefits of VSM include improved efficiency, increased productivity, enhanced customer satisfaction, and reduced costs.

How do I create a Value Stream Map?

+To create a Value Stream Map, define the scope, gather data, map the current state, identify waste, and design the future state.