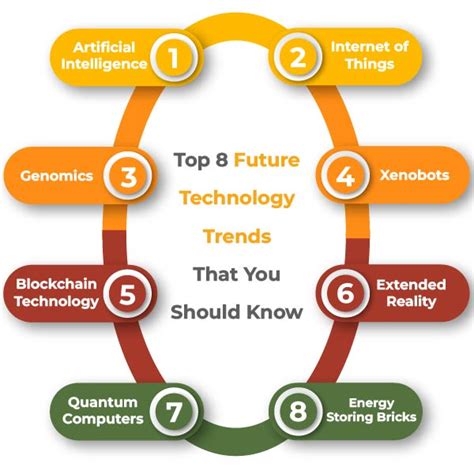

The tool tech industry is rapidly evolving, with innovations and trends emerging every year. From advancements in materials and manufacturing processes to the integration of cutting-edge technologies like AI and IoT, the industry is transforming at a breathtaking pace. In this article, we will explore the latest tool tech trends and innovations that are shaping the future of the industry.

Advancements in Materials and Manufacturing

One of the most significant trends in tool tech is the development of new materials and manufacturing processes. Advances in materials science have led to the creation of new materials with improved strength, durability, and resistance to corrosion. For example, the use of advanced ceramics and nanomaterials is becoming increasingly common in tooling applications. These materials offer improved wear resistance and longer tool life, resulting in reduced maintenance costs and increased productivity.

Nanomaterials and Nanostructures

Nanomaterials and nanostructures are being used to create tools with improved performance and functionality. For example, nanostructured coatings can be used to reduce friction and wear on cutting tools, resulting in improved surface finish and longer tool life. Additionally, nanomaterials can be used to create tools with improved thermal conductivity, resulting in more efficient heat transfer and reduced thermal deformation.Additive Manufacturing

Additive manufacturing (AM) is a rapidly growing trend in tool tech. AM allows for the creation of complex tool geometries and structures that cannot be produced using traditional manufacturing methods. This enables the creation of tools with improved performance and functionality, such as tools with internal cooling channels or complex surface geometries. AM also enables rapid prototyping and production, reducing lead times and increasing productivity.Integration of AI and IoT

The integration of AI and IoT is another significant trend in tool tech. AI can be used to analyze data from sensors and machines, enabling real-time monitoring and optimization of tool performance. For example, AI-powered predictive maintenance can be used to predict when a tool is likely to fail, enabling proactive maintenance and reducing downtime.

Predictive Maintenance

Predictive maintenance is a rapidly growing trend in tool tech. Predictive maintenance uses AI and machine learning algorithms to analyze data from sensors and machines, enabling real-time monitoring and optimization of tool performance. This enables proactive maintenance and reduces downtime, resulting in increased productivity and reduced maintenance costs.Smart Tools and Machines

Smart tools and machines are being used to improve tool performance and functionality. For example, smart cutting tools can be equipped with sensors and AI-powered software, enabling real-time monitoring and optimization of cutting parameters. This results in improved surface finish, reduced tool wear, and increased productivity.Electrification and Automation

Electrification and automation are also significant trends in tool tech. Electrification involves the use of electric motors and actuators to power tools and machines, resulting in improved efficiency and reduced emissions. Automation involves the use of robotics and machine learning algorithms to improve tool performance and functionality, resulting in increased productivity and reduced labor costs.

Electric Motors and Actuators

Electric motors and actuators are being used to power tools and machines, resulting in improved efficiency and reduced emissions. For example, electric motors can be used to power cutting tools, resulting in improved surface finish and reduced tool wear.Robotics and Machine Learning

Robotics and machine learning are being used to improve tool performance and functionality. For example, robots can be used to perform tasks such as assembly and inspection, resulting in increased productivity and reduced labor costs. Machine learning algorithms can be used to analyze data from sensors and machines, enabling real-time monitoring and optimization of tool performance.Gallery of Tool Tech Trends and Innovations

Conclusion: The Future of Tool Tech

The tool tech industry is rapidly evolving, with innovations and trends emerging every year. From advancements in materials and manufacturing processes to the integration of cutting-edge technologies like AI and IoT, the industry is transforming at a breathtaking pace. As we look to the future, it is clear that tool tech will continue to play a critical role in shaping the world around us.We hope this article has provided you with a comprehensive overview of the latest tool tech trends and innovations. Whether you are a manufacturer, engineer, or simply someone interested in the latest technology, we encourage you to stay up-to-date with the latest developments in the industry.

We invite you to share your thoughts and comments on the latest tool tech trends and innovations. How do you see the industry evolving in the future? What innovations and trends do you think will have the biggest impact? Share your insights and join the conversation!

What are some of the latest trends in tool tech?

+Some of the latest trends in tool tech include advancements in materials and manufacturing processes, integration of AI and IoT, electrification and automation, and additive manufacturing.

What is the role of AI in tool tech?

+AI is being used to analyze data from sensors and machines, enabling real-time monitoring and optimization of tool performance. AI can also be used to predict when a tool is likely to fail, enabling proactive maintenance and reducing downtime.

What is the future of tool tech?

+The future of tool tech is likely to be shaped by continued advancements in materials and manufacturing processes, integration of cutting-edge technologies like AI and IoT, and electrification and automation. As the industry continues to evolve, we can expect to see increased productivity, reduced maintenance costs, and improved tool performance.