The use of technology in various industries has led to significant advancements in recent years. One such innovation is the development of tech line coatings, which have revolutionized the way businesses operate. These coatings have been designed to provide a protective layer to various surfaces, enhancing their performance and extending their lifespan.

In this article, we will explore the five ways tech line coatings can boost performance and why they are becoming increasingly popular across different sectors.

What are Tech Line Coatings?

Tech line coatings refer to a range of surface treatment technologies that provide a thin, protective layer to various materials. These coatings can be applied to metals, plastics, and other surfaces to enhance their performance, durability, and resistance to wear and tear.

The use of tech line coatings has become increasingly popular due to their ability to provide a cost-effective and efficient solution to various industrial challenges. By applying a thin layer of coating to a surface, businesses can significantly reduce maintenance costs, improve productivity, and extend the lifespan of their equipment.

1. Improved Corrosion Resistance

One of the primary benefits of tech line coatings is their ability to provide improved corrosion resistance. Corrosion is a major concern for businesses operating in harsh environments, as it can lead to significant damage and maintenance costs.

By applying a tech line coating to a surface, businesses can create a barrier that prevents corrosion from occurring. This not only extends the lifespan of the equipment but also reduces the need for frequent maintenance and repairs.

How Tech Line Coatings Prevent Corrosion

Tech line coatings prevent corrosion by creating a thin, impermeable layer that prevents moisture and other corrosive substances from coming into contact with the surface. This layer can be made from a range of materials, including ceramics, polymers, and metals.

When a tech line coating is applied to a surface, it creates a strong bond that prevents corrosion from occurring. This bond is formed through a process known as adhesion, which involves the coating adhering to the surface at a molecular level.

2. Enhanced Wear Resistance

Another significant benefit of tech line coatings is their ability to provide enhanced wear resistance. Wear and tear is a major concern for businesses operating in harsh environments, as it can lead to significant damage and maintenance costs.

By applying a tech line coating to a surface, businesses can create a barrier that prevents wear and tear from occurring. This not only extends the lifespan of the equipment but also reduces the need for frequent maintenance and repairs.

How Tech Line Coatings Prevent Wear

Tech line coatings prevent wear by creating a thin, hard layer that prevents friction and abrasion from occurring. This layer can be made from a range of materials, including ceramics, polymers, and metals.

When a tech line coating is applied to a surface, it creates a strong bond that prevents wear from occurring. This bond is formed through a process known as adhesion, which involves the coating adhering to the surface at a molecular level.

3. Improved Thermal Resistance

Tech line coatings can also provide improved thermal resistance, which is essential for businesses operating in high-temperature environments. Thermal resistance refers to the ability of a material to withstand extreme temperatures without losing its structural integrity.

By applying a tech line coating to a surface, businesses can create a barrier that prevents heat from penetrating the surface. This not only extends the lifespan of the equipment but also reduces the risk of thermal shock and damage.

How Tech Line Coatings Provide Thermal Resistance

Tech line coatings provide thermal resistance by creating a thin, insulating layer that prevents heat from penetrating the surface. This layer can be made from a range of materials, including ceramics, polymers, and metals.

When a tech line coating is applied to a surface, it creates a strong bond that prevents heat from transferring to the surface. This bond is formed through a process known as adhesion, which involves the coating adhering to the surface at a molecular level.

4. Enhanced Electrical Insulation

Tech line coatings can also provide enhanced electrical insulation, which is essential for businesses operating in industries that require high-voltage equipment. Electrical insulation refers to the ability of a material to prevent the flow of electrical current.

By applying a tech line coating to a surface, businesses can create a barrier that prevents electrical current from flowing to the surface. This not only extends the lifespan of the equipment but also reduces the risk of electrical shock and damage.

How Tech Line Coatings Provide Electrical Insulation

Tech line coatings provide electrical insulation by creating a thin, non-conductive layer that prevents electrical current from flowing to the surface. This layer can be made from a range of materials, including ceramics, polymers, and metals.

When a tech line coating is applied to a surface, it creates a strong bond that prevents electrical current from flowing to the surface. This bond is formed through a process known as adhesion, which involves the coating adhering to the surface at a molecular level.

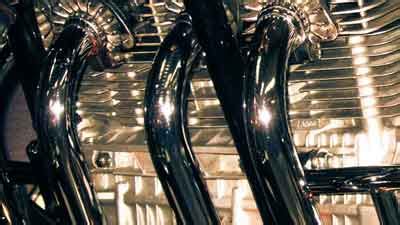

5. Improved Aesthetics

Finally, tech line coatings can also provide improved aesthetics, which is essential for businesses that require high-quality finishes. Aesthetics refer to the visual appearance of a material, and tech line coatings can enhance the appearance of a surface by providing a smooth, glossy finish.

By applying a tech line coating to a surface, businesses can create a barrier that prevents corrosion, wear, and tear from occurring. This not only extends the lifespan of the equipment but also improves its appearance.

How Tech Line Coatings Improve Aesthetics

Tech line coatings improve aesthetics by creating a thin, smooth layer that enhances the appearance of a surface. This layer can be made from a range of materials, including ceramics, polymers, and metals.

When a tech line coating is applied to a surface, it creates a strong bond that prevents corrosion, wear, and tear from occurring. This bond is formed through a process known as adhesion, which involves the coating adhering to the surface at a molecular level.

Gallery of Tech Line Coatings

What are tech line coatings?

+Tech line coatings are a range of surface treatment technologies that provide a thin, protective layer to various materials.

What are the benefits of tech line coatings?

+Tech line coatings provide improved corrosion resistance, enhanced wear resistance, improved thermal resistance, enhanced electrical insulation, and improved aesthetics.

How do tech line coatings work?

+Tech line coatings work by creating a thin, protective layer that prevents corrosion, wear, and tear from occurring.

In conclusion, tech line coatings are a revolutionary technology that can significantly enhance the performance of various surfaces. By providing improved corrosion resistance, enhanced wear resistance, improved thermal resistance, enhanced electrical insulation, and improved aesthetics, tech line coatings can extend the lifespan of equipment, reduce maintenance costs, and improve productivity.

We hope this article has provided you with a comprehensive understanding of the benefits and applications of tech line coatings. If you have any further questions or would like to learn more about this technology, please do not hesitate to contact us.

We encourage you to share your thoughts and experiences with tech line coatings in the comments section below. Your feedback is invaluable to us, and we look forward to hearing from you.