As industries continue to evolve and grow, the demand for skilled professionals who can oversee and optimize complex processes has never been higher. One such role is that of a Process Technician, also known as a Process Tech. In this article, we will delve into the world of Process Tech jobs, exploring the key roles and responsibilities that these professionals undertake.

Process Technicians are critical to the smooth operation of various industries, including manufacturing, oil and gas, and pharmaceuticals. They are responsible for ensuring that processes run safely, efficiently, and effectively, with a focus on minimizing waste and maximizing productivity. But what exactly does a Process Tech do, and what are the key roles that they play?

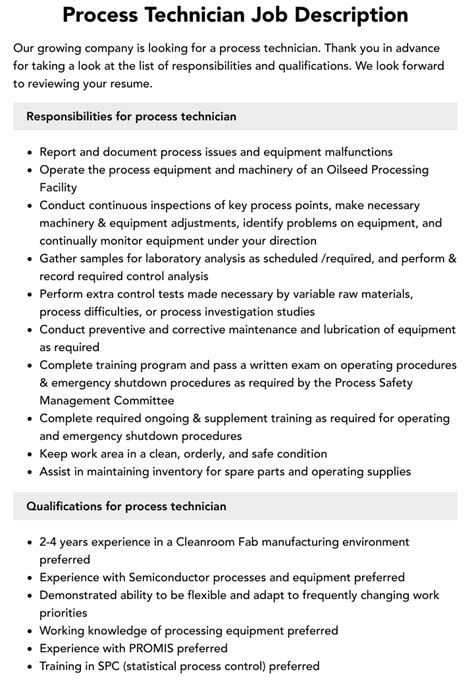

1. Process Monitoring and Troubleshooting

A Process Technician's primary responsibility is to monitor and control processes in real-time. This involves keeping a close eye on various parameters, such as temperature, pressure, and flow rates, to ensure that they are operating within designated limits. If issues arise, Process Techs must quickly identify the root cause and take corrective action to prevent disruptions or safety hazards.

To perform this role effectively, Process Techs must possess strong analytical and problem-solving skills, as well as the ability to think critically and make sound judgments under pressure.

2. Equipment Maintenance and Repair

Process Technicians are also responsible for performing routine maintenance and repairs on equipment to prevent breakdowns and minimize downtime. This includes tasks such as cleaning, lubricating, and replacing worn or damaged parts, as well as conducting regular inspections to identify potential issues before they become major problems.

Key Maintenance Activities

- Performing routine maintenance tasks, such as cleaning and lubricating equipment

- Conducting regular inspections to identify potential issues

- Replacing worn or damaged parts

- Troubleshooting and repairing equipment malfunctions

By staying on top of maintenance and repairs, Process Techs can help extend the lifespan of equipment, reduce the risk of accidents, and minimize the need for costly repairs.

3. Quality Control and Assurance

Process Technicians play a critical role in ensuring that products meet the required quality standards. This involves monitoring processes and testing products to ensure that they conform to specifications, as well as identifying and addressing any quality control issues that may arise.

Key Quality Control Activities

- Monitoring processes to ensure that they are operating within designated parameters

- Testing products to ensure that they meet quality standards

- Identifying and addressing quality control issues

- Implementing corrective actions to prevent quality control issues

By prioritizing quality control and assurance, Process Techs can help ensure that products are safe, reliable, and meet customer expectations.

4. Safety and Environmental Protection

Process Technicians have a critical role to play in ensuring that processes are operated safely and with minimal environmental impact. This involves identifying potential hazards, implementing safety protocols, and taking steps to minimize waste and emissions.

Key Safety and Environmental Activities

- Identifying potential hazards and implementing safety protocols

- Minimizing waste and emissions

- Ensuring compliance with safety and environmental regulations

- Participating in safety and environmental training programs

By prioritizing safety and environmental protection, Process Techs can help prevent accidents, reduce waste, and minimize the environmental impact of industrial processes.

5. Collaboration and Communication

Finally, Process Technicians must be able to collaborate and communicate effectively with other stakeholders, including operations personnel, maintenance teams, and management. This involves providing clear and concise information about process operations, identifying areas for improvement, and working together to implement changes.

Key Collaboration and Communication Activities

- Providing clear and concise information about process operations

- Identifying areas for improvement and recommending changes

- Collaborating with other stakeholders to implement changes

- Participating in training and development programs to enhance collaboration and communication skills

By working together with other stakeholders, Process Techs can help drive process improvements, enhance safety and quality, and contribute to the overall success of the organization.

Gallery of Process Tech Jobs

FAQs

What is a Process Technician?

+A Process Technician is a professional responsible for monitoring and controlling processes in various industries, including manufacturing, oil and gas, and pharmaceuticals.

What are the key roles of a Process Technician?

+The key roles of a Process Technician include process monitoring and troubleshooting, equipment maintenance and repair, quality control and assurance, safety and environmental protection, and collaboration and communication.

What skills do I need to become a Process Technician?

+To become a Process Technician, you will need strong analytical and problem-solving skills, as well as the ability to think critically and communicate effectively. You will also need to possess a strong understanding of process operations and safety protocols.

In conclusion, Process Technicians play a critical role in ensuring the safe and efficient operation of various industrial processes. By understanding the key roles and responsibilities of these professionals, we can better appreciate the importance of their work and the skills and knowledge required to succeed in this field.