Mastering Mtech bend fabrication requires a combination of technical knowledge, hands-on experience, and attention to detail. Mtech bend fabrication is a complex process that involves creating precise bends and curves in metal sheets or tubes using a combination of machine and manual techniques. Here are five ways to master Mtech bend fabrication and take your skills to the next level.

Understanding the Fundamentals of Mtech Bend Fabrication

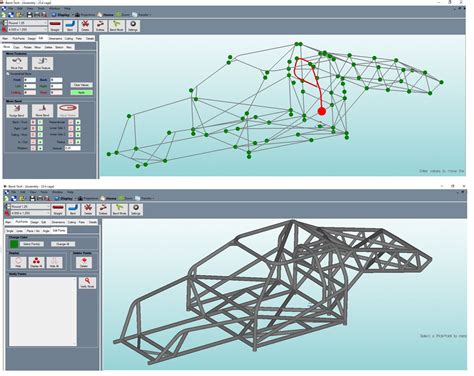

To master Mtech bend fabrication, it's essential to understand the fundamentals of the process. This includes understanding the different types of bends, such as V-bends, U-bends, and radius bends, as well as the various techniques used to create them. Familiarize yourself with the different tools and equipment used in Mtech bend fabrication, including the Mtech machine, bending dies, and forming rolls.

Key Concepts to Master

- Understanding the properties of different metals and their behavior when bent

- Familiarity with the Mtech machine and its various components

- Knowledge of different bending techniques, including V-bending, U-bending, and radius bending

- Understanding of the importance of precision and accuracy in Mtech bend fabrication

Developing Your Skills through Practice and Experience

Like any skill, mastering Mtech bend fabrication requires practice and experience. Start by working on simple projects and gradually move on to more complex ones. Practice different bending techniques, such as V-bending and U-bending, and experiment with different metals and tools. Join online forums and communities to connect with other Mtech bend fabrication enthusiasts and learn from their experiences.

Tips for Developing Your Skills

- Start with simple projects and gradually move on to more complex ones

- Practice different bending techniques and experiment with different metals and tools

- Join online forums and communities to connect with other Mtech bend fabrication enthusiasts

- Watch videos and tutorials to learn new techniques and improve your skills

Using the Right Tools and Equipment

Having the right tools and equipment is essential for mastering Mtech bend fabrication. Invest in a good quality Mtech machine and a set of bending dies and forming rolls. Familiarize yourself with the different tools and equipment used in Mtech bend fabrication, including measuring tools, cutting tools, and finishing tools.

Key Tools and Equipment to Master

- Mtech machine

- Bending dies

- Forming rolls

- Measuring tools, such as calipers and micrometers

- Cutting tools, such as band saws and hacksaws

- Finishing tools, such as files and sandpaper

Understanding the Importance of Safety and Quality Control

Safety and quality control are critical aspects of Mtech bend fabrication. Always wear protective gear, including gloves and safety glasses, when working with the Mtech machine and other tools. Inspect your work regularly to ensure that it meets the required standards of quality and precision.

Key Safety and Quality Control Measures to Master

- Wearing protective gear, including gloves and safety glasses

- Inspecting your work regularly to ensure quality and precision

- Following proper procedures for setting up and operating the Mtech machine

- Using the right materials and tools for the job

Staying Up-to-Date with the Latest Techniques and Technologies

The field of Mtech bend fabrication is constantly evolving, with new techniques and technologies emerging all the time. Stay up-to-date with the latest developments by attending workshops and seminars, reading industry publications, and joining online forums and communities.

Key Resources to Stay Up-to-Date

- Industry publications, such as magazines and journals

- Online forums and communities

- Workshops and seminars

- Manufacturer websites and technical support resources

What is Mtech bend fabrication?

+Mtech bend fabrication is a process of creating precise bends and curves in metal sheets or tubes using a combination of machine and manual techniques.

What are the different types of bends in Mtech bend fabrication?

+The different types of bends in Mtech bend fabrication include V-bends, U-bends, and radius bends.

What is the importance of safety and quality control in Mtech bend fabrication?

+Safety and quality control are critical aspects of Mtech bend fabrication, as they ensure that the work is done accurately and safely.

In conclusion, mastering Mtech bend fabrication requires a combination of technical knowledge, hands-on experience, and attention to detail. By following these five ways to master Mtech bend fabrication, you can take your skills to the next level and become a proficient Mtech bend fabrication technician. Remember to always stay up-to-date with the latest techniques and technologies, and to prioritize safety and quality control in your work.