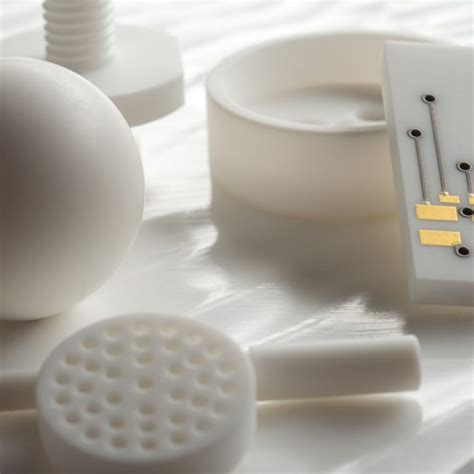

High tech ceramic innovations have revolutionized various industries, from aerospace and healthcare to electronics and energy. The unique properties of ceramics, such as their high strength, durability, and resistance to corrosion and extreme temperatures, make them an ideal material for a wide range of modern applications. In this article, we will explore the latest advancements in ceramic technology and their applications in different fields.

The Importance of Ceramics in Modern Technology

Ceramics have been used for centuries in various forms, from pottery and tableware to tiles and sanitary ware. However, with the advent of advanced technologies, ceramics have become a critical material in modern industries. Their unique combination of properties, such as high hardness, corrosion resistance, and thermal shock resistance, makes them an ideal choice for applications where metals and polymers may fail.

Recent advancements in ceramic technology have led to the development of new materials with improved properties, such as increased strength, toughness, and thermal conductivity. These advancements have opened up new possibilities for ceramics in various industries, from aerospace and defense to healthcare and energy.

Applications of High Tech Ceramics

High tech ceramics have a wide range of applications in various industries, including:

Aerospace and Defense

In the aerospace and defense industries, high tech ceramics are used in various applications, such as:

- Missile guidance systems: Ceramics are used in the guidance systems of missiles due to their high strength, durability, and resistance to extreme temperatures.

- Armor plating: Ceramic armor plating is used to protect military vehicles and personnel from ballistic threats due to its high hardness and resistance to penetration.

- Satellite components: Ceramics are used in satellite components, such as antennas and sensors, due to their high thermal conductivity and resistance to radiation.

Healthcare

In the healthcare industry, high tech ceramics are used in various applications, such as:

- Dental implants: Ceramic dental implants are used due to their high strength, durability, and biocompatibility.

- Orthopedic implants: Ceramic orthopedic implants, such as hip and knee replacements, are used due to their high wear resistance and biocompatibility.

- Surgical instruments: Ceramic surgical instruments, such as scalpels and forceps, are used due to their high hardness and resistance to corrosion.

Electronics

In the electronics industry, high tech ceramics are used in various applications, such as:

- Microelectromechanical systems (MEMS): Ceramics are used in MEMS devices, such as sensors and actuators, due to their high thermal conductivity and resistance to corrosion.

- Electronic substrates: Ceramic substrates are used in electronic devices, such as smartphones and laptops, due to their high thermal conductivity and resistance to corrosion.

- Dielectric resonators: Ceramic dielectric resonators are used in microwave devices, such as filters and antennas, due to their high dielectric constant and low loss tangent.

Energy

In the energy industry, high tech ceramics are used in various applications, such as:

- Nuclear reactors: Ceramics are used in nuclear reactors due to their high thermal conductivity and resistance to radiation.

- Solar cells: Ceramic solar cells are used due to their high efficiency and resistance to corrosion.

- Fuel cells: Ceramic fuel cells are used due to their high thermal conductivity and resistance to corrosion.

Advantages of High Tech Ceramics

High tech ceramics offer several advantages over traditional materials, including:

- High strength and durability

- Resistance to corrosion and extreme temperatures

- High thermal conductivity

- Biocompatibility

- Resistance to radiation

These advantages make high tech ceramics an ideal material for a wide range of modern applications, from aerospace and defense to healthcare and energy.

Challenges and Limitations

Despite the advantages of high tech ceramics, there are several challenges and limitations to their use, including:

- High cost: High tech ceramics can be expensive to produce, which can limit their use in certain applications.

- Complexity: The production process for high tech ceramics can be complex, which can limit their use in certain applications.

- Limited availability: High tech ceramics may not be widely available, which can limit their use in certain applications.

Despite these challenges and limitations, high tech ceramics are expected to play an increasingly important role in various industries in the coming years.

Future of High Tech Ceramics

The future of high tech ceramics looks promising, with several emerging trends and technologies expected to drive growth in the industry. Some of the emerging trends and technologies include:

- Nanoceramics: Nanoceramics are ceramic materials with particle sizes in the nanoscale range. They are expected to have improved properties, such as increased strength and toughness.

- Energy storage: High tech ceramics are expected to play an increasingly important role in energy storage applications, such as batteries and supercapacitors.

- Biomedical applications: High tech ceramics are expected to play an increasingly important role in biomedical applications, such as implants and surgical instruments.

In conclusion, high tech ceramics have revolutionized various industries, from aerospace and healthcare to electronics and energy. Their unique properties, such as high strength, durability, and resistance to corrosion and extreme temperatures, make them an ideal material for a wide range of modern applications. As the industry continues to evolve, we can expect to see new and emerging trends and technologies that will drive growth and innovation in the field of high tech ceramics.

What are high tech ceramics?

+High tech ceramics are advanced ceramic materials with improved properties, such as high strength, durability, and resistance to corrosion and extreme temperatures.

What are the advantages of high tech ceramics?

+High tech ceramics offer several advantages, including high strength and durability, resistance to corrosion and extreme temperatures, and biocompatibility.

What are the challenges and limitations of high tech ceramics?

+High tech ceramics can be expensive to produce, and their production process can be complex. Additionally, they may not be widely available.