Effective equipment maintenance is crucial for ensuring the smooth operation of any organization, reducing downtime, and increasing productivity. A well-planned maintenance schedule helps in identifying potential issues before they become major problems, thereby saving time and resources. In this article, we will discuss the importance of equipment maintenance, its benefits, and provide guidance on creating a maintenance schedule template in Excel.

Why Equipment Maintenance is Important

Equipment maintenance is essential for preventing unexpected breakdowns, reducing repair costs, and extending the lifespan of equipment. Regular maintenance also helps in identifying potential safety hazards, ensuring compliance with regulatory requirements, and improving overall equipment performance.

Benefits of Equipment Maintenance

- Increased Productivity: Regular maintenance helps in reducing downtime, ensuring that equipment is always available when needed.

- Reduced Repair Costs: Identifying and addressing potential issues before they become major problems saves time and resources.

- Improved Safety: Regular maintenance helps in identifying potential safety hazards, reducing the risk of accidents and injuries.

- Extended Equipment Lifespan: Proper maintenance extends the lifespan of equipment, delaying the need for replacement.

- Compliance with Regulatory Requirements: Regular maintenance ensures compliance with regulatory requirements, reducing the risk of fines and penalties.

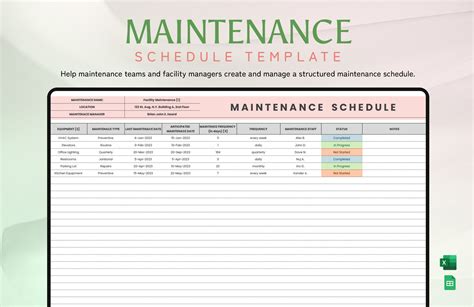

Creating an Equipment Maintenance Schedule Template in Excel

Creating a maintenance schedule template in Excel is a straightforward process that can be completed in a few steps. Here's a step-by-step guide to creating a basic maintenance schedule template:

Step 1: Set up a new Excel spreadsheet

Open a new Excel spreadsheet and set up a table with the following columns:

- Equipment ID: A unique identifier for each piece of equipment.

- Equipment Name: The name of each piece of equipment.

- Maintenance Type: The type of maintenance required (e.g., routine, preventive, corrective).

- Maintenance Frequency: The frequency of maintenance (e.g., daily, weekly, monthly).

- Due Date: The date when maintenance is due.

- Completed Date: The date when maintenance was completed.

- Notes: Any additional notes or comments.

Step 2: Enter equipment data

Enter the equipment data into the table, including the equipment ID, name, maintenance type, frequency, and due date.

Step 3: Create a maintenance schedule

Create a maintenance schedule by using the data entered in the previous step. You can use the Conditional Formatting feature in Excel to highlight cells that require attention.

Step 4: Set up reminders

Set up reminders for upcoming maintenance tasks by using the ** notifications** feature in Excel.

Step 5: Review and update the schedule

Regularly review and update the maintenance schedule to ensure that it remains accurate and effective.

Tips for Creating an Effective Maintenance Schedule

- Identify critical equipment: Identify critical equipment that requires regular maintenance to prevent downtime and losses.

- Use a preventive maintenance approach: Use a preventive maintenance approach to identify potential issues before they become major problems.

- Include all equipment: Include all equipment in the maintenance schedule, regardless of its importance or criticality.

- Review and update the schedule regularly: Regularly review and update the maintenance schedule to ensure that it remains accurate and effective.

- Train personnel: Train personnel on the maintenance schedule and ensure that they understand their roles and responsibilities.

Equipment Maintenance Schedule Template Excel Free Download

You can download a free equipment maintenance schedule template in Excel from various online sources, including:

- Microsoft Office Templates

- Excel-Easy

- Vertex42

These templates provide a basic structure for creating a maintenance schedule and can be customized to meet your specific needs.

Gallery of Equipment Maintenance Schedule Templates

FAQs

- What is an equipment maintenance schedule? An equipment maintenance schedule is a plan that outlines the maintenance tasks required to keep equipment in good working condition.

- Why is equipment maintenance important? Equipment maintenance is important because it helps prevent unexpected breakdowns, reduces repair costs, and extends the lifespan of equipment.

- How do I create an equipment maintenance schedule? You can create an equipment maintenance schedule by identifying critical equipment, using a preventive maintenance approach, and including all equipment in the schedule.

- What are the benefits of equipment maintenance? The benefits of equipment maintenance include increased productivity, reduced repair costs, improved safety, extended equipment lifespan, and compliance with regulatory requirements.

By following these steps and tips, you can create an effective equipment maintenance schedule that helps prevent downtime, reduces repair costs, and extends the lifespan of your equipment.