In the world of precision engineering, achieving micron-level accuracy is crucial for producing high-quality components. One of the key technologies that enable this level of precision is diamond machining. Diamond machining is a technique that utilizes diamond-coated cutting tools to machine a wide range of materials, including metals, ceramics, and composites. By mastering diamond machining technology, manufacturers can produce components with unparalleled accuracy and surface finish.

The Importance of Precision Engineering Precision engineering is a critical aspect of various industries, including aerospace, automotive, medical devices, and semiconductor manufacturing. In these industries, components with precise dimensions and surface finishes are essential for ensuring optimal performance, safety, and reliability. The consequences of imprecise components can be severe, ranging from reduced product lifespan to catastrophic failures. Therefore, manufacturers must invest in advanced technologies that enable them to produce components with micron-level accuracy.

Diamond Machining: A Game-Changer for Precision Engineering Diamond machining is a revolutionary technology that has transformed the precision engineering landscape. By utilizing diamond-coated cutting tools, manufacturers can machine materials with unprecedented accuracy and surface finish. Diamond machining offers several advantages over traditional machining techniques, including:

- Enhanced accuracy: Diamond-coated cutting tools can achieve tolerances as low as ±1 micron, making them ideal for producing components with precise dimensions.

- Improved surface finish: Diamond machining can produce surface finishes as low as Ra 0.01 μm, reducing the need for subsequent processing steps.

- Increased material range: Diamond-coated cutting tools can machine a wide range of materials, including metals, ceramics, and composites.

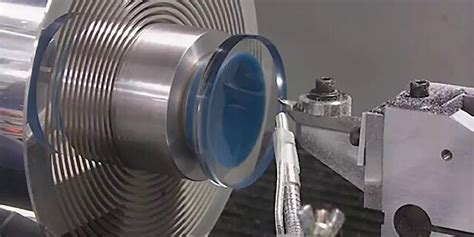

Working Mechanisms of Diamond Machining Diamond machining involves the use of diamond-coated cutting tools to machine materials. The process can be broken down into several key stages:

- Tool preparation: Diamond-coated cutting tools are prepared using advanced techniques, such as chemical vapor deposition (CVD) or physical vapor deposition (PVD).

- Machine setup: The diamond-coated cutting tool is mounted on a precision machine tool, which is designed to provide micron-level accuracy.

- Machining process: The material is machined using the diamond-coated cutting tool, which removes material through a process of shear deformation.

- Inspection and quality control: The machined component is inspected and quality-controlled to ensure that it meets the required specifications.

Applications of Diamond Machining Diamond machining has a wide range of applications across various industries, including:

- Aerospace: Diamond machining is used to produce components for aircraft and spacecraft, such as engine components, satellite components, and missile guidance systems.

- Automotive: Diamond machining is used to produce components for vehicles, such as engine components, transmission components, and fuel injection systems.

- Medical devices: Diamond machining is used to produce components for medical devices, such as implants, surgical instruments, and diagnostic equipment.

- Semiconductor manufacturing: Diamond machining is used to produce components for semiconductor manufacturing, such as wafers, dies, and packaging materials.

Benefits of Diamond Machining Diamond machining offers several benefits over traditional machining techniques, including:

- Enhanced accuracy: Diamond-coated cutting tools can achieve tolerances as low as ±1 micron, making them ideal for producing components with precise dimensions.

- Improved surface finish: Diamond machining can produce surface finishes as low as Ra 0.01 μm, reducing the need for subsequent processing steps.

- Increased material range: Diamond-coated cutting tools can machine a wide range of materials, including metals, ceramics, and composites.

- Reduced material waste: Diamond machining can reduce material waste by enabling the production of components with complex geometries.

- Increased productivity: Diamond machining can increase productivity by enabling the production of components at high speeds and with minimal tool wear.

Challenges and Limitations of Diamond Machining While diamond machining offers several advantages, it also presents several challenges and limitations, including:

- High tool costs: Diamond-coated cutting tools are expensive to produce and maintain.

- Limited tool life: Diamond-coated cutting tools have a limited lifespan and must be replaced frequently.

- Material limitations: Diamond machining is limited to materials that can be machined using diamond-coated cutting tools.

- Machine requirements: Diamond machining requires specialized machine tools that are designed to provide micron-level accuracy.

Future Developments in Diamond Machining The field of diamond machining is continuously evolving, with ongoing research and development focused on improving tool life, reducing tool costs, and expanding the range of materials that can be machined. Some of the future developments in diamond machining include:

- Advanced tool coatings: Researchers are developing new tool coatings that offer improved wear resistance and longer tool life.

- Novel machining techniques: Researchers are developing novel machining techniques, such as laser-assisted diamond machining, that offer improved accuracy and surface finish.

- Machine tool advancements: Machine tool manufacturers are developing advanced machine tools that offer improved accuracy, precision, and productivity.

Conclusion Diamond machining is a revolutionary technology that has transformed the precision engineering landscape. By mastering diamond machining technology, manufacturers can produce components with unparalleled accuracy and surface finish. While diamond machining presents several challenges and limitations, ongoing research and development are focused on improving tool life, reducing tool costs, and expanding the range of materials that can be machined. As the field of diamond machining continues to evolve, it is likely to play an increasingly important role in the production of high-precision components for a wide range of industries.

Gallery of Diamond Machining Technology

FAQ Section

What is diamond machining?

+Diamond machining is a technique that utilizes diamond-coated cutting tools to machine a wide range of materials, including metals, ceramics, and composites.

What are the benefits of diamond machining?

+Diamond machining offers several benefits, including enhanced accuracy, improved surface finish, increased material range, reduced material waste, and increased productivity.

What are the challenges and limitations of diamond machining?

+The challenges and limitations of diamond machining include high tool costs, limited tool life, material limitations, and machine requirements.