In today's fast-paced industrial landscape, automation has become a crucial component for businesses seeking to enhance efficiency, reduce costs, and increase productivity. As companies strive to remain competitive, the need for expert industrial automation solutions has never been more pressing. Control Techs NW is a leading provider of industrial automation solutions, dedicated to helping businesses achieve their goals through innovative and effective technology.

Industrial automation involves the use of control systems, robots, and other technologies to optimize industrial processes. This can include everything from manufacturing and production to material handling and logistics. By automating these processes, businesses can significantly reduce labor costs, improve product quality, and increase overall efficiency.

However, implementing industrial automation solutions can be a complex and daunting task. That's where Control Techs NW comes in – with a team of experienced engineers and technicians, we provide expert guidance and support to help businesses navigate the world of industrial automation.

Expertise in Industrial Automation

At Control Techs NW, we possess extensive knowledge and expertise in industrial automation. Our team has years of experience working with a wide range of industries, from food processing and pharmaceuticals to oil and gas and manufacturing. We understand the unique challenges and requirements of each industry and are well-equipped to provide tailored solutions that meet your specific needs.

Our expertise includes:

-

Control System Design and Implementation

We design and implement control systems that meet the specific needs of your business. Our team works closely with you to understand your goals and objectives, and develops a customized control system that optimizes your industrial processes.

-

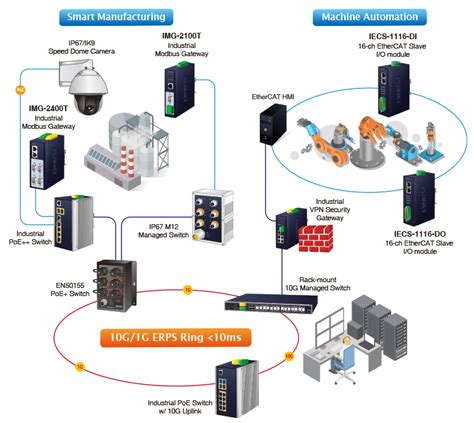

Robotics and Machine Automation

We provide robotics and machine automation solutions that improve efficiency and reduce labor costs. Our team integrates robots and machines into your existing processes, ensuring seamless operation and maximum productivity.

-

SCADA and HMI Systems

We design and implement SCADA (Supervisory Control and Data Acquisition) and HMI (Human-Machine Interface) systems that provide real-time monitoring and control of your industrial processes. Our team ensures that your SCADA and HMI systems are intuitive, user-friendly, and meet your specific needs.

Benefits of Industrial Automation

Industrial automation offers numerous benefits for businesses, including:

-

Increased Efficiency

Automation enables businesses to streamline their processes, reducing labor costs and improving productivity. By automating tasks, businesses can free up resources and focus on higher-value activities.

-

Improved Product Quality

Automation helps businesses to improve product quality by reducing the likelihood of human error. With automation, processes are performed consistently and accurately, resulting in higher-quality products.

-

Reduced Labor Costs

Automation reduces labor costs by minimizing the need for manual labor. Businesses can significantly reduce their labor costs, while also improving productivity and efficiency.

-

Enhanced Safety

Automation improves safety by reducing the risk of accidents and injuries. With automation, hazardous tasks are performed by machines, reducing the risk of human error and improving overall safety.

Challenges of Industrial Automation

While industrial automation offers numerous benefits, it also presents several challenges. Some of the common challenges faced by businesses include:

-

High Upfront Costs

Implementing industrial automation solutions can be expensive, requiring significant upfront investment. Businesses must carefully consider the costs and benefits before deciding to implement automation.

-

Complexity

Industrial automation involves complex technologies and systems, requiring specialized knowledge and expertise. Businesses must have access to experienced engineers and technicians to ensure successful implementation.

-

Integration with Existing Systems

Industrial automation solutions must be integrated with existing systems, which can be a complex and challenging task. Businesses must ensure that their automation solutions are compatible with their existing infrastructure.

Future of Industrial Automation

The future of industrial automation is exciting and rapidly evolving. Some of the emerging trends and technologies include:

-

Artificial Intelligence and Machine Learning

AI and ML are being increasingly used in industrial automation, enabling businesses to optimize their processes and improve productivity.

-

Internet of Things (IoT)

IoT is transforming industrial automation, enabling businesses to connect their devices and systems, and providing real-time monitoring and control.

-

Cloud Computing

Cloud computing is being used in industrial automation, enabling businesses to access their data and systems remotely, and improving collaboration and productivity.

We invite you to share your thoughts on industrial automation and its applications. How has automation impacted your business or industry? What challenges have you faced, and how have you overcome them? Share your experiences and insights in the comments section below.

What is industrial automation?

+Industrial automation involves the use of control systems, robots, and other technologies to optimize industrial processes.

What are the benefits of industrial automation?

+Industrial automation offers numerous benefits, including increased efficiency, improved product quality, reduced labor costs, and enhanced safety.

What are the challenges of industrial automation?

+Some of the common challenges faced by businesses include high upfront costs, complexity, and integration with existing systems.