Artificial Intelligence and Advanced Analytics (AI) have revolutionized the way businesses operate, making data-driven decisions more efficient and effective. However, with the increasing complexity of modern manufacturing processes, the need for a standardized approach to quality control has become more pressing than ever. This is where the AIAG Control Plan Template comes in – a powerful tool designed to help organizations streamline their quality control processes and ensure compliance with industry standards.

In this article, we will delve into the world of AIAG Control Plan Templates, exploring their importance, benefits, and most importantly, providing a step-by-step guide on how to master them.

Understanding the AIAG Control Plan Template

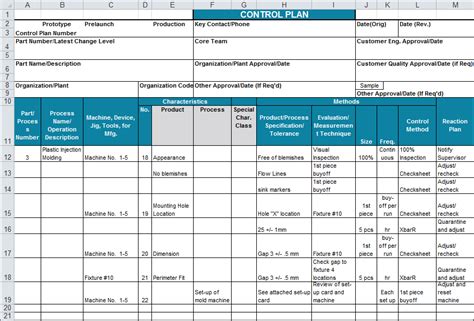

The AIAG Control Plan Template is a standardized document used to outline the quality control process for a specific product or process. Developed by the Automotive Industry Action Group (AIAG), this template provides a structured approach to identifying and mitigating potential quality risks, ensuring that products meet customer requirements and industry standards.

The template is divided into several sections, each addressing a critical aspect of the quality control process, including:

- Process Description

- Product Characteristics

- Control Methods

- Measurement Techniques

- Reaction Plan

- Verification and Validation

Benefits of Using the AIAG Control Plan Template

By implementing the AIAG Control Plan Template, organizations can reap numerous benefits, including:

- Improved quality control processes

- Enhanced customer satisfaction

- Reduced defects and waste

- Increased efficiency and productivity

- Compliance with industry standards and regulations

8 Steps to Mastering the AIAG Control Plan Template

Mastering the AIAG Control Plan Template requires a thorough understanding of its components and how to effectively use them. Here are the 8 steps to help you get started:

Step 1: Understand the Template Structure

Before you begin, it's essential to understand the template's structure and content. Familiarize yourself with the different sections and how they relate to each other.

Step 2: Identify Product Characteristics

Identify the critical product characteristics that need to be controlled. This includes dimensions, material properties, and other relevant attributes.

Step 3: Determine Control Methods

Determine the control methods that will be used to ensure the product characteristics are met. This includes inspection, testing, and validation techniques.

Step 4: Develop Measurement Techniques

Develop measurement techniques to ensure that the control methods are effective. This includes defining measurement systems, sampling plans, and data analysis methods.

Step 5: Establish a Reaction Plan

Establish a reaction plan to address potential quality issues. This includes defining corrective actions, containment procedures, and communication protocols.

Step 6: Verify and Validate the Control Plan

Verify and validate the control plan to ensure it is effective and efficient. This includes conducting audits, reviews, and continuous improvement activities.

Step 7: Monitor and Update the Control Plan

Monitor the control plan and update it as necessary. This includes reviewing performance metrics, addressing changes in product or process, and ensuring compliance with industry standards.

Step 8: Train and Communicate with Stakeholders

Train and communicate with stakeholders on the control plan, including employees, suppliers, and customers. This includes providing training on the template, its components, and its application.

Best Practices for Implementing the AIAG Control Plan Template

To ensure successful implementation of the AIAG Control Plan Template, follow these best practices:

- Use a cross-functional team to develop and review the control plan

- Ensure that the control plan is aligned with industry standards and regulations

- Use data-driven decision-making to drive continuous improvement

- Communicate the control plan to all stakeholders

- Monitor and update the control plan regularly

Conclusion

Mastering the AIAG Control Plan Template is a critical step in ensuring quality control and compliance with industry standards. By following the 8 steps outlined in this article, organizations can develop effective control plans that drive continuous improvement and customer satisfaction.

Don't hesitate to share your experiences and tips on implementing the AIAG Control Plan Template in the comments section below.

What is the AIAG Control Plan Template?

+The AIAG Control Plan Template is a standardized document used to outline the quality control process for a specific product or process.

What are the benefits of using the AIAG Control Plan Template?

+By implementing the AIAG Control Plan Template, organizations can improve quality control processes, enhance customer satisfaction, reduce defects and waste, increase efficiency and productivity, and ensure compliance with industry standards and regulations.

How do I implement the AIAG Control Plan Template?

+To implement the AIAG Control Plan Template, follow the 8 steps outlined in this article, including understanding the template structure, identifying product characteristics, determining control methods, developing measurement techniques, establishing a reaction plan, verifying and validating the control plan, monitoring and updating the control plan, and training and communicating with stakeholders.