Variable Frequency Drives (VFDs) are crucial components in modern industrial and commercial settings, enabling the efficient and precise control of AC motors. The technology has revolutionized the way we manage motor speed, torque, and power consumption, leading to significant energy savings, increased productivity, and reduced maintenance costs.

At the heart of this innovation is the AC Tech Variable Frequency Drive, a product designed to optimize motor performance and reliability. In this article, we will delve into the world of VFDs, exploring their functionality, benefits, and applications, with a focus on the AC Tech Variable Frequency Drive.

What is a Variable Frequency Drive (VFD)?

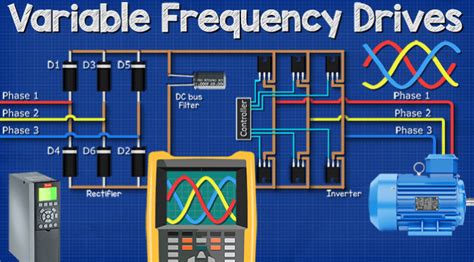

A Variable Frequency Drive is an electronic device that controls the speed of an AC motor by adjusting the frequency and voltage of the power supplied to it. This is achieved by converting the AC power from the mains to a DC signal, which is then converted back to AC with a variable frequency. By modifying the frequency, the VFD can regulate the motor speed, enabling precise control over the application.

Key Components of a VFD

A typical VFD consists of several key components:

- Converter: This stage converts the AC power from the mains to a DC signal.

- Inverter: The inverter converts the DC signal back to AC with a variable frequency.

- Control Unit: The control unit regulates the VFD's operation, including speed, torque, and other parameters.

- Motor: The AC motor is the final component, which is controlled by the VFD.

How Does a VFD Work?

The operation of a VFD can be broken down into several stages:

- Power Conversion: The converter stage converts the AC power from the mains to a DC signal.

- DC Link: The DC signal is filtered and stored in a DC link capacitor.

- Inverter: The inverter converts the DC signal back to AC with a variable frequency.

- Motor Control: The VFD's control unit regulates the motor speed and torque by adjusting the frequency and voltage of the output signal.

Benefits of Using a VFD

Variable Frequency Drives offer numerous benefits, including:

- Energy Efficiency: VFDs optimize motor performance, reducing energy consumption and costs.

- Increased Productivity: Precise control over motor speed and torque enables improved process control and productivity.

- Reduced Maintenance: VFDs minimize motor wear and tear, reducing maintenance costs and downtime.

- Improved Process Control: VFDs enable precise control over motor speed and torque, improving process control and product quality.

Applications of VFDs

Variable Frequency Drives are used in a wide range of applications, including:

- Pumps and Fans: VFDs optimize pump and fan performance, reducing energy consumption and costs.

- Conveyors and Material Handling: VFDs regulate conveyor speed and torque, improving process control and productivity.

- HVAC Systems: VFDs optimize HVAC system performance, reducing energy consumption and costs.

- Industrial Processes: VFDs are used in various industrial processes, such as textile manufacturing, paper production, and chemical processing.

AC Tech Variable Frequency Drive

The AC Tech Variable Frequency Drive is a product designed to optimize motor performance and reliability. With its advanced features and user-friendly interface, the AC Tech VFD is an ideal solution for a wide range of applications.

Conclusion

In conclusion, Variable Frequency Drives are essential components in modern industrial and commercial settings, enabling the efficient and precise control of AC motors. The AC Tech Variable Frequency Drive is a product designed to optimize motor performance and reliability, offering numerous benefits and applications.

Final Thoughts

As technology continues to evolve, VFDs will play an increasingly important role in optimizing motor performance and reducing energy consumption. The AC Tech Variable Frequency Drive is a testament to this innovation, providing a reliable and efficient solution for a wide range of applications.

What is a Variable Frequency Drive (VFD)?

+A Variable Frequency Drive (VFD) is an electronic device that controls the speed of an AC motor by adjusting the frequency and voltage of the power supplied to it.

How does a VFD work?

+A VFD works by converting the AC power from the mains to a DC signal, which is then converted back to AC with a variable frequency.

What are the benefits of using a VFD?

+The benefits of using a VFD include energy efficiency, increased productivity, reduced maintenance, and improved process control.